I need some help with a tail for a single seater.The tail that I have in mind is the same vertical fin and rudder as Magni,ELA,MTO etc.The horizontal stabilazor should be higher almost like the butterfly gyros.My questions:1) What is correct size for the horizontal stab if moved up ?2) What is the correct thickness of the stab , I have seen very thin to aerofoil ones.3) What weight should be packed on the stab to test it. Does the stab needs to be fitted in a zero angle of attack or negative angle of attack situation? I was thinking negative as you don’t want the stab to generate lift when applying full power. This is my theory and could be totally wrong, please help.

Announcement

Collapse

No announcement yet.

Tail design

Collapse

X

-

Hi T bird, what sort of machine do you have or building? a single place, open frame or canopy, lightweight 2 stroke or suby or rotax 4 banger?I am only asking because the tail area and horizontal stab area are all related to how the machine is set up. Also, what will you be doing with the machine? mustering or high energy local play flying, or travelling long distances? As an example, a mustering machine would suffer from a huge horizontal stab, where a cross country machine would probably benefit. It also depends on whether the aerofoil surfaces are in the relative slip stream or in the prop blast..... so please give us more details on your machine

-

Hi T-Bird,If you lend us a hand and spill the beans on the gross weight estimate, the rotor diameter, and the intended placement of the 25% point of the horizontal stabilizer, then I"ll be able to crunch some numbers for you about surface area suggestions. I agree with your general observations - VS and rudder to be proportionate to the average European tandem, and HS to be a t-tail or almost a t-tail aka the Monarch Butterfly.For my new single seater I"m going through precisely the same process of evaluation and selection as you are doing, and have arrived at the same basic parameters.As for HS thickness I would suggest 12% to 15%, and airfoil I would suggest none other that the good old NACA 0015 (or 0012), a tried and true symmetrical airfoil used on Bell 47s, Hughes 300s and 500s, and popular (in 0012) with Sikorsky"s in particular for rotors and horizontal stabilizers. The flat plate HSs that appear to dominate the Australian homebuilt fleet are universally sub-optimal, although perhaps better than nothing at all. This is because, as Max writes, their effectiveness as a stabilizing surface is extremely limited to within several degrees either side. Worse still, the flat plate at zero angle of attack just doesn"t work at all, because it only begins to function at several degrees AOA, then stalls at about 8 to 10 deg AOA. On the other hand, a properly shaped airfoil section will always generate a detectable moment to the relative airflow other that at aerodynamic zero. I should also chuck in the mantra that a HS will only be effective provided the moment arm is long enough for it to generate a proper pitching moment. Much as I admire Dr Igor Bensen for some of the work he did, the fitting of the "stone guard" HS commonplace on the Bensen machines, usually under the engine and only maybe 18 inches to 24 inches back from the rotor hub

Comment

-

My theory and why I find it necessary to know more info on the machine, is same as you Mark.... if the machine is to be open frame or just a small half pod or fairing, putting on an empennage that is designed for the European machines with huge barn sided (as the airflow sees it in slip) tubs onto a machine with little or no pod, would, in my opinion, make a machine that is so stable and horizontally stabilized that any usual fun flight charactoristics may be all but eliminated because the tail just wont allow any unusual (but normal for a gyro) directional movement.

Comment

-

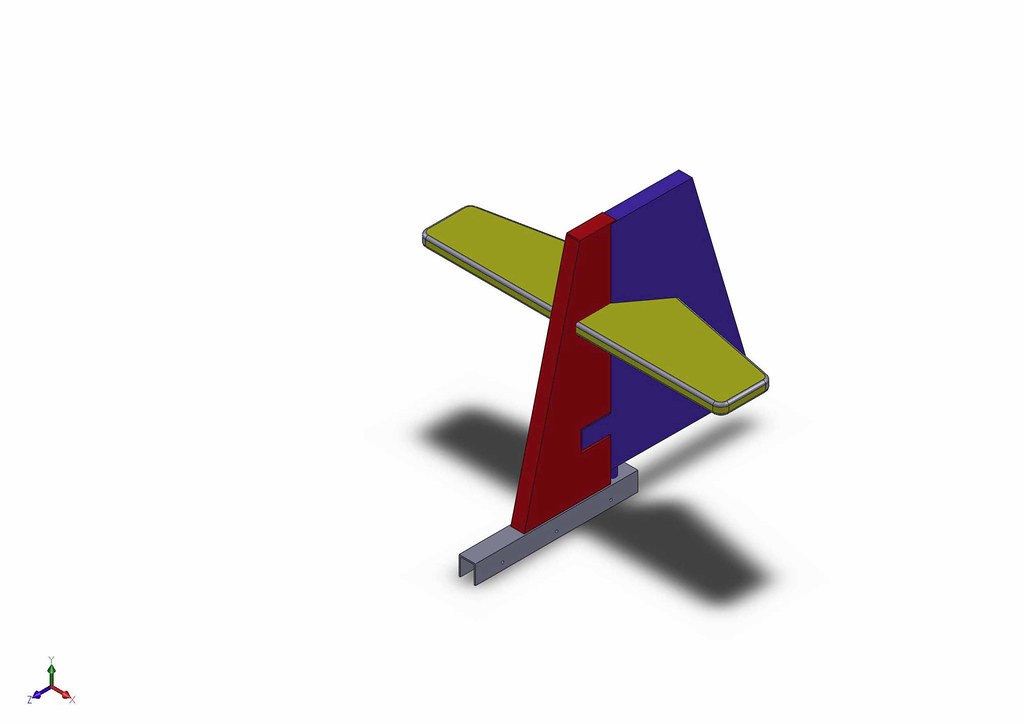

What I am aiming for is Rotax 58225 Feet rotorsAll up weight fuel and pilot 350 kgCentre line thrustOpen cockpit I have looked at the NACA 0012 aerofoil and have the coordinates, but am a bit lost as to how I would get the foam in the NACA shapeHere is the design I am working on. Missing the cockpit as my Solidwork skill are self taught,

Comment

-

go to http://www.gyrocopteronline.com/index.php?go=15download new version hornet gyro.about page 115 talks about

Remember: no matter where you go, there you are

Comment

-

Howdy T-Bird,I"m glad you can use Solidworks because I can"t, but I get the basic idea. My initial impressions are you have made a reasonable start although your forward portion of the keel beam is a bit too long, while the aft portion of the keel beam is unnecessarily short. the vertical stabilizer doesn"t need to be kinked up like it is, while you need to double your rudder area (I agree completely with Paul Bruty who says that the fixed portion of a VS-rudder combined should be no more than 40% of the total area, or in other words the hinged rudder should be not less than 60% of the combined area.)The engine needs to be lowered to achieve a configuration closer to CLT (difficult to do if your prop is gonna keep clear of the keel), or the forward keel and seat assembly raised relative to the engine/prop combination.I am currently about 3/5th completed writing the ASRA Technical Manual. Chapters 17 and 18 are all about rotor selection and how to design a gyroplane layout, so if you send me an email I can send you those draft chapters. My email is mr@vicbar.com.auCheers,Mark ReganMelbourne - Tech Mgr

Comment

-

https://www.youtube.com/watch?v=R0ZCnR_g6ZUusing a hotwiredon"t know if you put a spar in the stab!, or how they do it.If it goes in the middle I suppose one would glue in a spar, then glue the two halves [top and bottom] together, then cut the HS profile after it is set.

Remember: no matter where you go, there you are

Comment

-

Hi MarkThanks for your reply. You said that the keel beam is a bit too long.I have based it on the hornets measurement which is 1441 mm for the forward keel.The Hornet"s total keel is 3020 mm = 1441 forward portion , 511 transition portion , 1068 mm tail boomMy keel is 180 mm longer at 3200 mm. The longer portion sits in the rear section.How much longer then should the rear portion be and how much sorter the front portion.As for the rudderI will use the same rudder area as Magni , ELA but the horizontal part will move up. CLTAgreed that I can move the engine still down by a bit. I have already turned the 582 gearbox upside down.What is the recommended prop clearance Kinked tailI never liked a straight keel like the Magni and I prefer the ELA, MTO tail. I just find it easier to land.RossM Thanks for the linksI have got hold of Divinycell foam for the tail. Which I will shape.It will be vacuum bagged with composites.

Comment

-

Just confirming what I said earlier, in my personal opinion, putting a mega tail designed with the area to stabilize a euro tub onto an open frame lightweight gyro would look out of place for one, be far to restrictive of the gyro type things a lightweight gyro should be able to do, will end up unnecessary bulk, drag and weight..... and possibly all for nothing, because once you fly it and realise the "joy" is not in the machine, it will probably be removed for something more practical and suitable....I guess in my mind it would be like fitting a genuine V8 supercar wing designed for a 250kmh track car..... onto a mini moke.... or truing to graft the empennage of a citation onto a Cessna 172....Edit: In the Gyro News, spring 1998, page 21=23 Jeff Henley-Smith wrote a very good article called "back to basics"" about overbuilding gyros, it is a very good read. If anyone hasn"t got old gyro news mags, a cd can be bought from ASRA that has every magazine on file... some fantastic information in the ols gyro news mags, well worth reading and taking notice of.

Comment

Comment